In this second instalment of ‘How a Turbo Works’ series – Part 2, we discuss the various parts of a turbo and how they all play an important role in producing more power.

Components

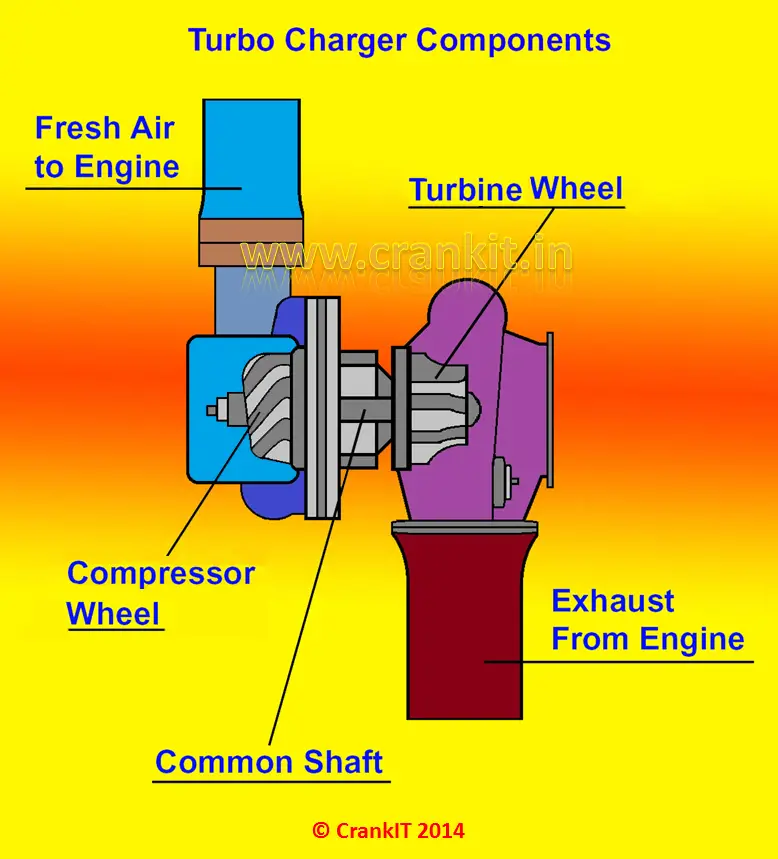

For a turbo to work it has to have four main components listed below and illustrated.

- Turbine wheel

- Compressor/Impeller wheel

- Center Hub Rotating Assembly (C.H.R.A.)

- Canonical housing

The turbine and impeller wheels are housed at opposite sides of the Centre Hub Rotating Assembly. This is also known as the C.H.R.A.

The housings fitted around the compressor and turbine wheels suck in and direct the gas through the turbo. The size and shape of the wheels dictate the performance characteristics of the overall turbo.

Often the same basic turbocharger assembly will be available from the manufacturer with multiple AR* choices for the turbine housing and sometimes the compressor cover.

We mentioned earlier the turbine and impeller wheels ‘size and shape of the wheels dictate the performance’. Generally, the larger the turbine wheel and compressor wheel, the larger the flow capacity. Measurements and shapes can vary, as well as curvature and the number of blades on the wheels all introduce a varying factor as to how well the turbo will perform.

‘size and shape of the wheels dictate the performance’

The Centre Hub Rotating Assembly (C.H.R.A.) houses a single shaft that connects and suspends the compressor and impeller wheels. At the rotating speeds the turbo wheels spin, bearings are necessary to have it rotate with minimal friction. This is usually performed by a thrust or ball bearing lubricated by a constant supply of pressurized oil. The C.H.R.A. can also be “water-cooled” by allowing the engine coolant to be circulated in place of oil.

If you found this article interesting, we are sure will enjoy

part 3 of How a Turbo Works.

Found the answer you were looking for… take a look at our eBay store to purchase the equipment you need. Click here to go to our eBay store

* The area of the cone to radius from centre hub is expressed as a ratio (AR, A/R, or A:R)