Turbocharging is very common on diesel engines in conventional cars, in trucks, locomotives, for marine and heavy machinery applications. In fact, for current automotive applications, non-turbocharged diesel engines are becoming increasingly rare. Diesels are particularly suitable for turbocharging for several reasons:

Naturally-aspirated diesels will develop less power than a petrol engine of the same size, and will weigh significantly more because diesel engine require heavier, stronger components. This gives such engines a poor power-to-weight ratio; turbocharging can dramatically improve this P:W ratio, with large power gains for a very small (if any) increase in weight. Diesel engines require more robust construction because they already run at very high compression ratio and at high temperatures so they generally require little additional reinforcement to be able to cope with the addition of the turbocharger. Petrol engines often require extensive modification for turbocharging. Diesel engines have a narrower band of engine speeds at which they operate, thus making the operating characteristics of the turbocharger over that “rev range” less of a compromise than on a petrol-powered engine. Diesel engines blow nothing but air into the cylinders during cylinder charging, squirting fuel into the cylinder only after the intake valve has closed and compression has begun. Petrol engines differ from this in that both fuel and air are introduced during the intake cycle and both are compressed during the compression cycle. The higher intake charge temperatures of forced-induction engines reduces the amount of compression that is possible with a petrol engine, whereas diesel engines are far less sensitive to this.

Today, turbocharging is most commonly used on two types of engines: Petrol engines in high-performance cars and diesel engines in transportation and other industrial equipment. Small cars in particular benefit from this technology, as there is often little room to fit a larger-output (and physically larger) engine. Saab is a leader in production car turbochargers, starting with the 1978 Saab 99; all current Saab models are turbocharged with the exception of the 9-7X. The Porsche 944 utilized a turbo unit in the 944 Turbo (Porsche internal model number 951), to great advantage, bringing its 0-100 km/h (0-60 mph) times very close to its contemporary non-turbo “big brother”, the Porsche 928.

In the 1980s, when turbocharged production cars became common, they gained a reputation for being difficult to handle. The tuned engines fitted to the cars, and the often primitive turbocharger technology meant that power delivery was unpredictable and the engine often suddenly delivered a huge boost in power at certain speeds. Some drivers said this made cars such as the BMW 2002 and the Porsche 911 exciting to drive, requiring high levels of skill. Others said the cars were difficult and often dangerous. As turbocharger technology improved, it became possible to produce turbocharged engines with a smoother, more predictable but just as effective power delivery.

Chrysler Corporation was an innovator of turbocharger use in the 1980s. Many of their production vehicles, for example the Chrysler LeBaron, Dodge Daytona, Dodge Shadow/Plymouth Sundance twins, and the Dodge Spirit/Plymouth Acclaim twins were available with turbochargers, and they proved very popular with the public. They are still considered competitive vehicles today, and the experience Chrysler obtained in observing turbochargers in real-world conditions has allowed them to further turbocharger technology with the PT Cruiser Turbo, the Dodge SRT-4 and the Dodge Caliber SRT-4.

Small car turbos are increasingly being used as the basis for small jet engines used for flying model aircraft—though the conversion is a highly specialised job—one not without its dangers. Jet engine enthusiasts have constructed home-built jet engines from automotive turbochargers, often running on propane and using a home-built combustion canister plumbed in between the high pressure side of the turbo’s compressor and the intake side of the turbine. An oil supply for the bearings is still needed, usually provided by an electric pump. Starting such home-built jets is usually achieved by blowing air through the unit with a compressor or a domestic leaf-blower. Making these engines is not an easy task- unless the combustion canister design is correct the engine will either fail to start, fail to stabilise once running or even over-rev and destroy itself.

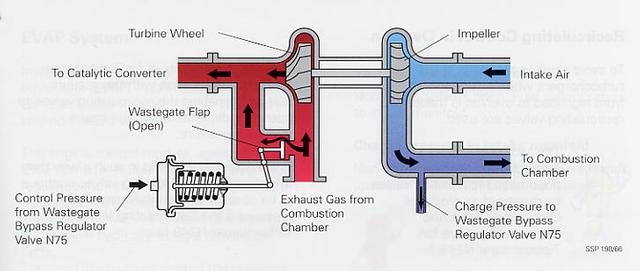

Most modern turbocharged aircraft use an adjustable wastegate. The wastegate is controlled manually, or by a pneumatic/hydraulic control system, or, as is becoming more and more common, by a flight computer. In the interests of engine longevity, the wastegate is usually kept open, or nearly so, at sea level to keep from overboosting the engine. As the aircraft climbs, the wastegate is gradually closed, maintaining the manifold pressure at or above sea level. In aftermarket applications, aircraft turbochargers sometimes do not overboost the engine, but rather compress ambient air to sea level pressure. For this reason, such aircraft are sometimes referred to as being turbo-normalised. Most applications produced by the major manufacturers (Beech, Cessna, Piper and others) increase the maximum engine intake air pressure by as much as 35%. Special attention to engine cooling and component strength is required because of the increased combustion heat and power.

Turbo-Alternator is a form of turbocharger that generates electricity instead of boosting engine’s airflow. On September 21, 2005, Foresight Vehicle announced the first known implementation of such unit for cars, under the name TIGERS (Turbo-generator Integrated Gas Energy Recovery System).